Bearing normally is only regarded as common standard part so that application design will not be analyzed accurately. It is not strange to see too large carriage with small horse, or small carriage with too big horse! However since application conditions are so different that bearings’ application design is extremely important during the design phase of equipment.

Based on decades of successful supporting experience and years of in-depth research by the TWB application design team, we have formed a unique value in many application fields. In addition to the existing product series, it can also design customized products for customers and provide analysis and guidance on bearing application design. Including: selection of bearing type, determination of clearance, bearing configuration, lubrication mode, installation design, friction heating and theoretical calculation.

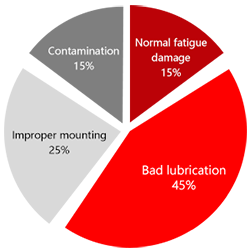

The bearing life we generally talk about refers to the total revolutions of any rolling element or any raceway in a bearing before spalling fatigue occurs, or the working hours at a certain speed. The bearing life discussed in most textbooks is also the theoretical design life around fatigue life. However, in many cases, the actual service life of the bearing is far from the theoretical fatigue life. According to statistics, more than 80% of the early failure of the bearing is not caused by the normal fatigue of the bearing. As shown in the figure on the right, only 15% of bearing damage is theoretical fatigue damage. Most bearings have been damaged due to poor lubrication, improper installation or pollution before running to bearing fatigue damage.

In a broad sense, the service life of bearings depends on: type selection, working conditions, bearing design, raw materials manufacturing process, heat treatment, installation & adjustment, sealing, lubrication, etc. These factors depend on each other and affect each other. Any one of these factors can affect the bearing life when the bearing type is determined, the rest factors will jointly affect the life of the bearing. TWB engineers can analyze which of the many elements is the most important according to the customer’s actual situation, and propose an overall solution.

Based on decades of successful supporting experience and years of in-depth research by the TWB application design team, we have formed a unique value in many application fields. In addition to the existing product series, we can also design customized products for customers and provide analysis and guidance on bearing application and design.